Internal production of Multicrystalline Silicon Ingots.

Import and distribution of silicon, wafers and the semi-finished products used in the production of photovoltaic modules (Cells, EVA, Backsheets, Junction Boxes, Glass, Aluminum Profiles). Availability of materials with different specifications according to the types of modules produced. Quick deliveries in Italy and Europe thanks to direct distribution from the Alessandria warehouse.

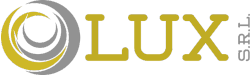

Polysilicon

Silicon is the most widely used base material for the production of photovoltaic modules and is the main component of solar cells. It is a semiconducting element that offers the electronic properties needed to convert solar energy into electricity through the photovoltaic effect. Because of its electronic properties, abundance, and versatility, silicon has become the material of choice for the production of photovoltaic modules. Continued research and innovation in the field are helping to further improve the efficiency and performance of silicon solar modules, making solar energy increasingly competitive as a renewable and sustainable energy source.

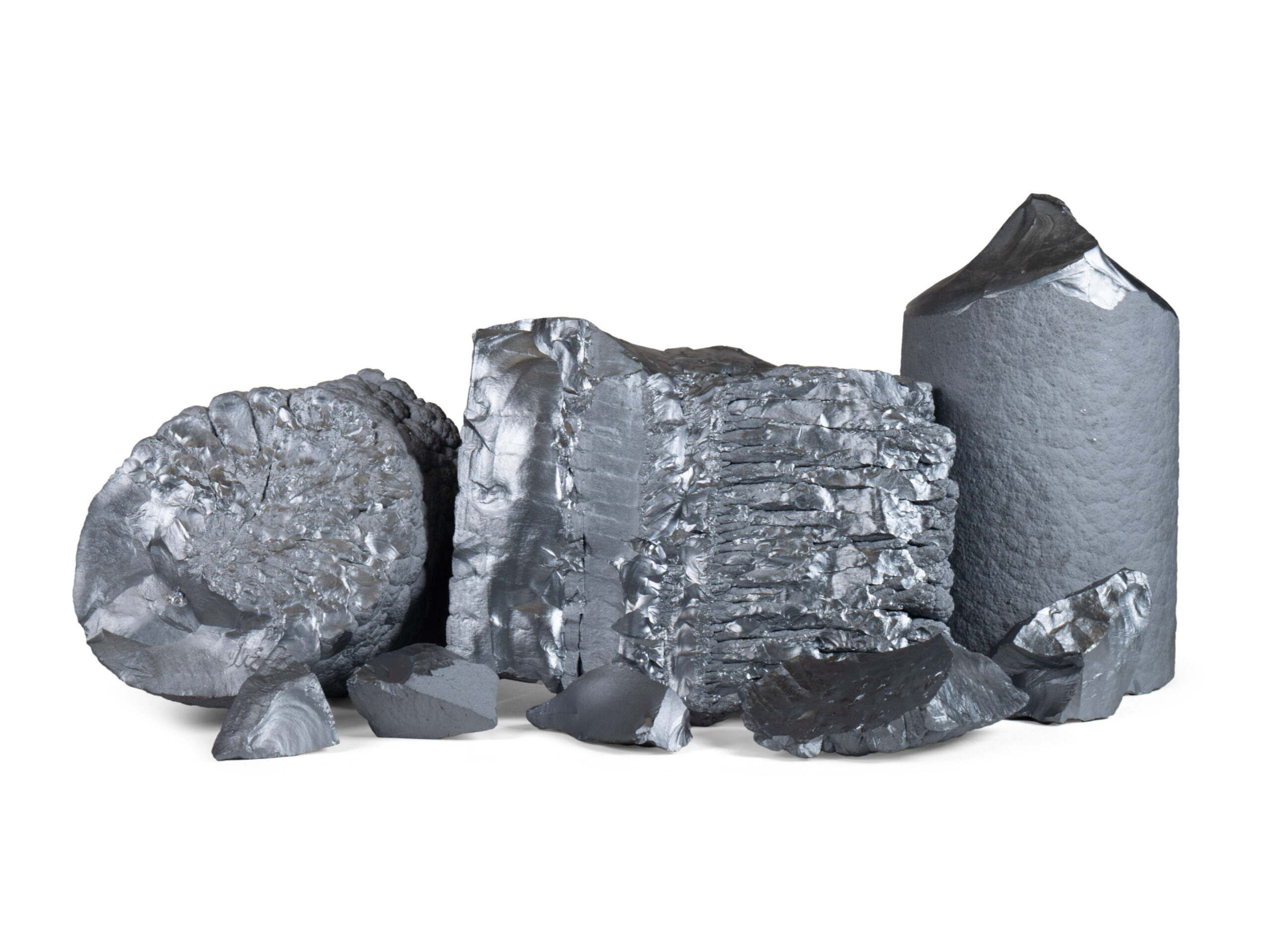

Ingots

Through a process of fusion and subsequent solidification, silicon is transformed into an ingot of different sizes depending on the technology used (Polycrystalline, Monocrystalline, etc.). The resulting ingot is then squared to obtain regular-shaped bricks, whose dimensions are those of the wafers that will be obtained. The brick is polished through a polishing process and is ready to be further sliced into wafers.

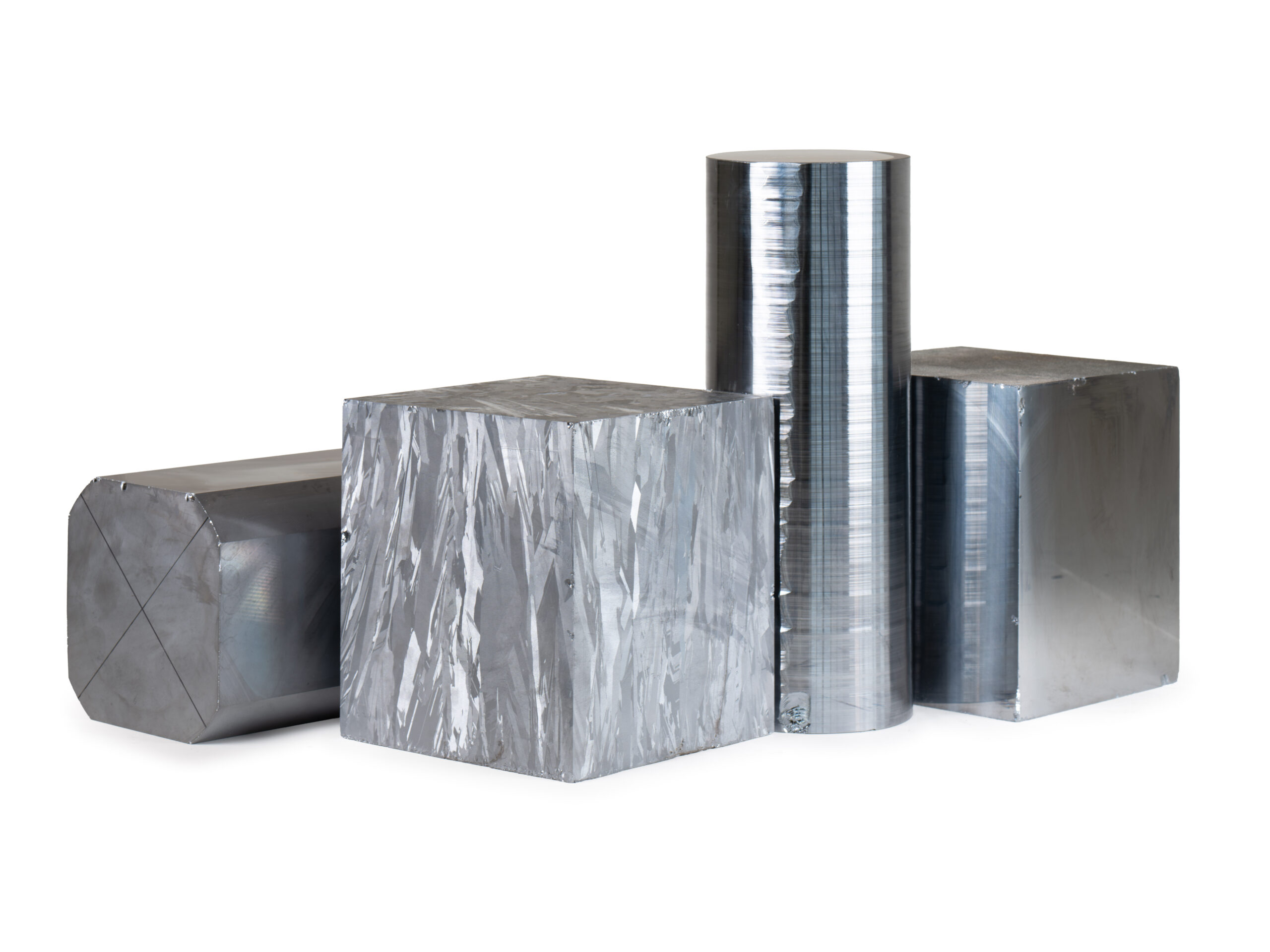

Wafers

A wafer is the “slice” of silicon that, when properly processed, will become a photovoltaic cell. Through a cutting process, bricks are sliced into wafers of different sizes and thicknesses. More recent manufacturing developments have led to the use of cells cut in half or one-third. It is therefore the wafers that are cut to these sizes. The wafer is the “core” of the photovoltaic panel; it can be multi or monocrystalline, depending on the ingot growth process.

Cells

Through various chemical processes, the wafer is transformed into a photovoltaic cell. The cell can be multi or monocrystalline, depending on the wafer type. Technological development has led to a steady increase in cell size and the number of busbars through which current is transmitted. In recent years, new technologies have been developed that lead to having the contact points of the cell on the back of the cell.

Glasses

Glass sheets used for the production of photovoltaic modules. Of different sizes, the glasses have benefited from a special anti-reflective treatment (ARC) aimed at increasing the productivity of the PV module. Suitable for the production of standard or BIPV PV modules. They can be presented Textured or ARC, with SPF certificate.

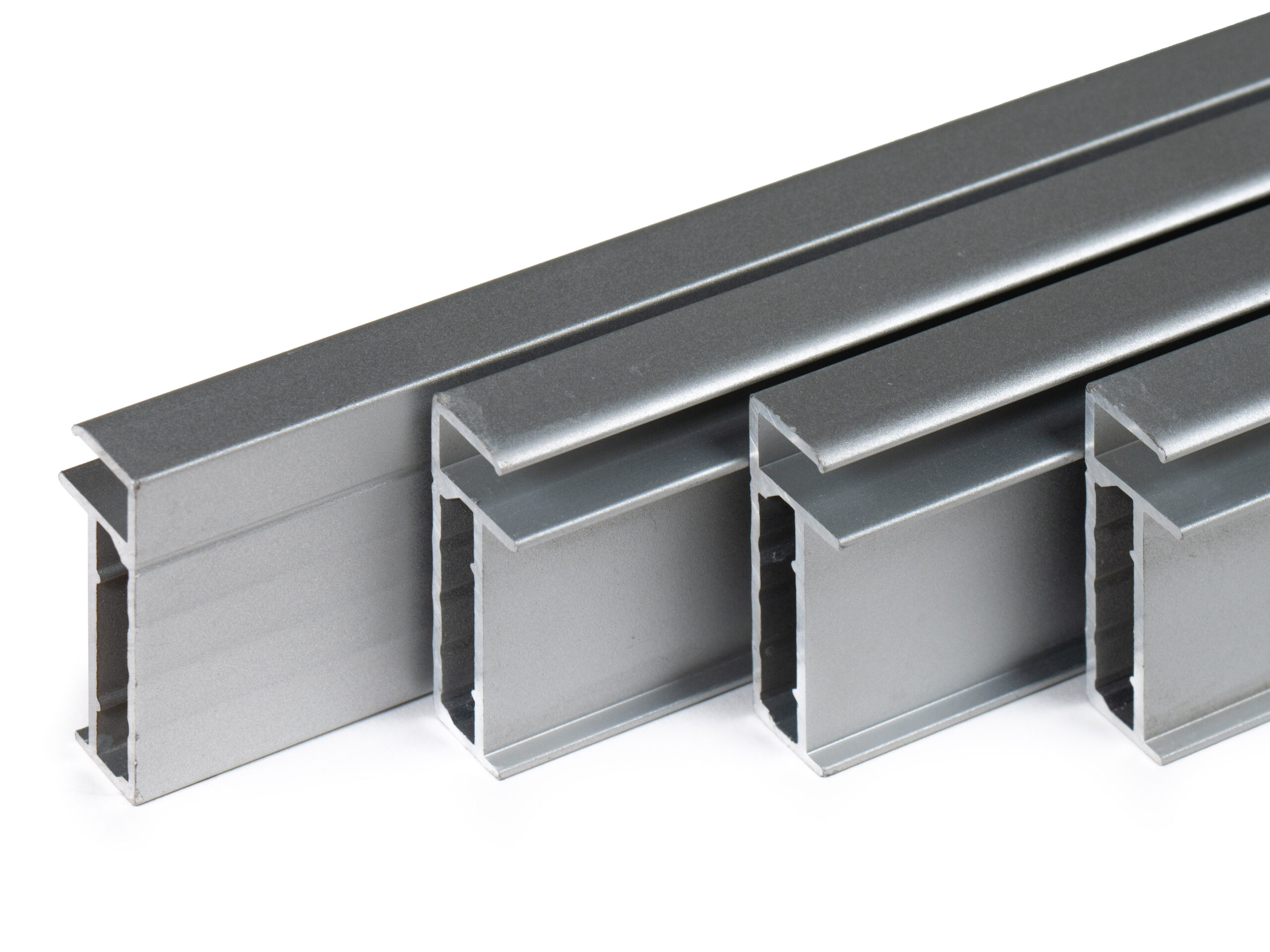

Frames

Aluminum profiles frame the PV module, sealing it from water infiltration. The frames are available in different sizes and different section designs. Generally silver in color, they can also be had in other colors such as black for full black module production or red for architectural integration. Anodized aluminum 10 um -25 Um and colored, 6063 alloys, 6005 in T5 or T6.

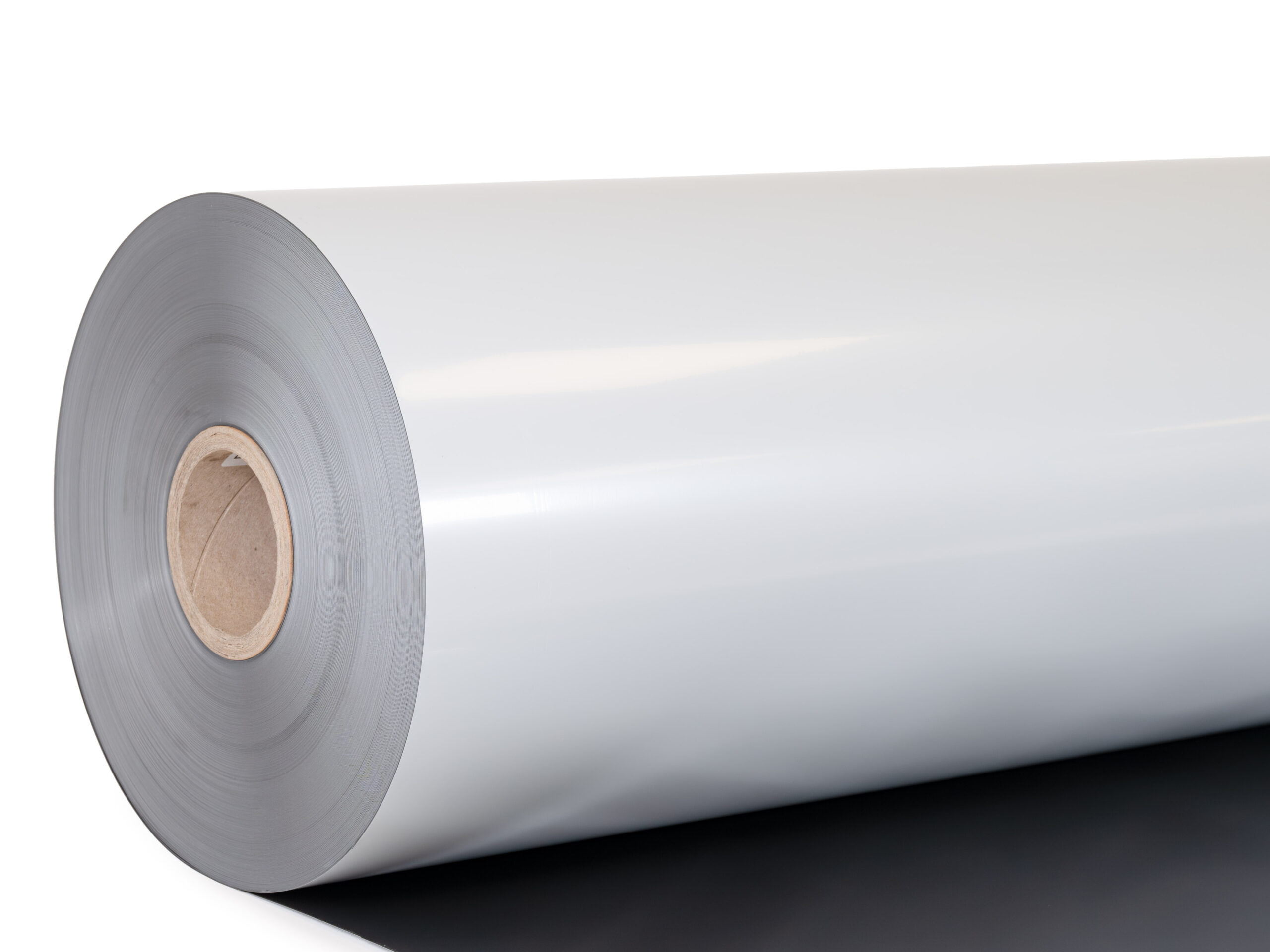

Backsheet

Backsheet is the rear part of the PV module. It is a vinyl film on which the cells encapsulated within the EVA rest. The product is available with different specifications and sizes. Different colors are available: white/white for standard modules, black/black for full black modules, or transparent for special applications.

EVA

EVA (Ethylene Vinyl Acetate) is a thermoplastic film used in the production of photovoltaic modules. Cell strings are encapsulated within a front and back layer of EVA so that they remain immobile during the manufacturing process. The characteristics of EVA allow the transmission of the sun’s rays its flexibility. Various sizes are available. POE and EPE are also available.

Junction Boxes

Junction boxes are the terminal part of the module. From the boxes come out the cables that connect one module to another on the same string and conduct the current produced by the panel. Different types of modules require different types of Junction boxes, all distributed by Lux. Also available with different cable lengths. Junction boxes for high performance, 0 to 5 diodes, with or without cable. Certifications 1000 Vdc – 1500 Vdc, UL, TUV.